Deep Offshore Technology: The Future of Offshore Exploration

The Evolution of Deep Offshore Technology

When people hear the term “deep offshore technology,” they often assume it’s just about drilling deeper to extract oil and gas. However, the reality is much more complex. The advancements in deep-sea exploration and drilling are not just about reaching new depths but also about enhancing efficiency, sustainability, and safety in offshore operations.

From advanced deep-sea drilling technology to AI-powered monitoring systems, offshore exploration has undergone a massive transformation. With increasing demand for energy and the rising importance of offshore renewable energy, the industry is shifting towards more innovative solutions that go beyond conventional offshore exploration and drilling solutions. In this blog, we’ll explore how cutting-edge developments are reshaping the future of subsea technology for offshore drilling and revolutionizing offshore exploration.

The Future of Offshore Oil and Gas Exploration Technology

The future of offshore oil and gas exploration technology will focus on enhanced efficiency, safety, and sustainability. Innovations like AI, robotics, and automation will streamline operations, while technologies such as autonomous underwater vehicles (AUVs) will improve data collection and hazard detection. Additionally, the integration of renewable energy sources into offshore platforms will reduce environmental impact. As these technologies evolve, offshore exploration will become safer, more efficient, and more aligned with global sustainability efforts.

Breaking the Myth: It’s Not Just About Oil and Gas

Many believe that offshore drilling rigs are only meant for oil and gas extraction. However, the truth is that modern offshore energy infrastructure supports multiple industries, including renewable energy, marine conservation, and even scientific exploration.

Key Trends Shaping Deep-Sea Exploration and Drilling

The offshore industry is evolving rapidly with groundbreaking innovations that enhance efficiency, safety, and sustainability. Here are some key trends leading this transformation:

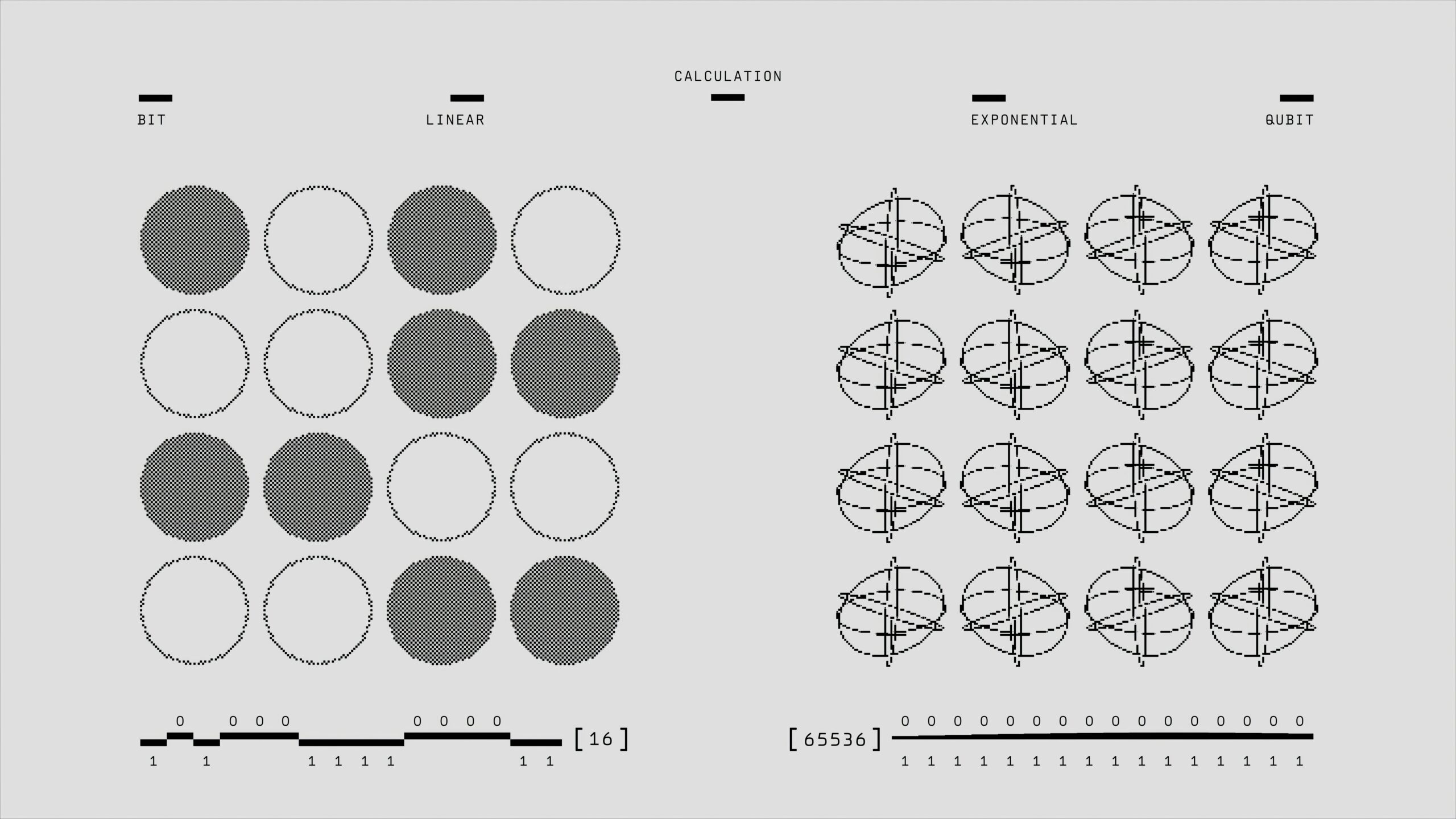

1. AI-Powered Offshore Exploration

Artificial intelligence is playing a crucial role in modern offshore oil storage solutions and exploration. AI-driven systems can predict equipment failures, optimize drilling operations, and improve offshore risk assessment. For example, AI-powered offshore asset integrity management systems can analyze structural weaknesses in pipelines, preventing major disasters before they occur.

2. Autonomous Underwater Vehicles (AUVs) for Deep-Sea Exploration

Gone are the days when manual intervention was required for deep-sea inspections. Today, autonomous underwater vehicles (AUVs) equipped with advanced sensors and cameras can perform high-precision surveys in ultra-deep waters. These AUVs are revolutionizing subsea pipeline inspection, making it faster, more efficient, and cost-effective.

3. Floating Offshore Wind Farms

The offshore energy industry is not just about fossil fuels anymore. Floating offshore wind farms are gaining traction, providing a sustainable alternative to traditional energy sources. These floating wind turbines harness the power of ocean winds, contributing to offshore power generation without the need for large land-based infrastructure.

4. High-Pressure Deep-Sea Drilling Innovations

As companies explore ultra-deepwater drilling and solutions, they face extreme pressure and temperature conditions. To combat this, engineers have developed next-gen high-pressure deep-sea drilling systems, utilizing cutting-edge materials and AI-driven monitoring tools to ensure safety and efficiency.

5. Offshore Carbon Capture Technology

With growing concerns about climate change, the offshore industry is adopting offshore carbon capture technology to reduce emissions from oil and gas extraction. These technologies help capture CO2 emissions at offshore sites and store them safely beneath the seabed, supporting a more sustainable energy future.

The Road Ahead: What’s Next for Offshore Exploration?

The future of deep offshore technology is not limited to oil and gas. As the industry embraces innovations in offshore energy production, we can expect more advanced solutions that focus on sustainability, efficiency, and safety. From cutting-edge offshore engineering techniques to AI-driven automation, the next decade will be a game-changer for subsea technology for offshore drilling.

Best Practices for Deep Offshore Drilling Operations

Best practices for deep offshore drilling operations focus on safety, efficiency, and environmental protection. Key practices include conducting thorough risk assessments, using advanced technology like automated drilling systems and real-time monitoring, performing regular equipment maintenance, and minimizing environmental impact through eco-friendly drilling fluids and waste management. Continuous employee training and adherence to safety protocols are crucial, along with compliance with regulatory standards. By following these best practices, offshore drilling operations can enhance safety, reduce risks, and support sustainable practices.

Breaking the Myth: More Depth Means More Risk

Many assume that drilling deeper into the ocean automatically increases the risks involved. While deeper drilling does present challenges, advancements in advanced deep-sea drilling technology and high-pressure deep-sea drilling solutions have made operations safer and more efficient than ever before.

Ensuring Safety and Efficiency in Offshore Drilling

One of the biggest priorities in offshore exploration and drilling solutions is to ensure safety while maximizing efficiency. Offshore risk assessment strategies now integrate AI-driven predictive analytics to detect potential hazards before they escalate. Combined with subsea artificial intelligence, this approach allows companies to prevent costly failures and minimize environmental risks.

In addition, cost-effective deep offshore infrastructure solutions are streamlining offshore operations. Modern subsea well intervention techniques use remotely operated vehicles (ROVs) and autonomous underwater vehicles (AUVs) to perform maintenance tasks without the need for human divers, improving both safety and efficiency.

Overcoming Challenges in Ultra-Deepwater Drilling

Ultra-deepwater drilling and solutions demand highly specialized technologies to withstand extreme underwater pressures. The development of offshore structural integrity monitoring systems ensures that drilling rigs and platforms remain stable even in harsh environments.

Another major challenge is offshore corrosion control. Deep-sea structures are exposed to saltwater, leading to corrosion over time. Innovations in marine oil spill prevention and anti-corrosion coatings are now extending the lifespan of offshore assets, making offshore asset integrity management a key focus area for the industry.

How AI is Transforming Deep Offshore Technology

AI is significantly transforming deep offshore technology by improving operational efficiency, safety, and sustainability. Advanced AI algorithms are being used to analyze real-time data from offshore platforms, allowing for predictive maintenance and reducing downtime. By identifying potential issues before they escalate, AI helps prevent costly failures and enhances overall system reliability.

In deepwater drilling, AI is optimizing drilling processes by adjusting parameters in real time, improving the precision and efficiency of operations. AI-powered autonomous underwater vehicles (AUVs) and remotely operated vehicles (ROVs) are being used for subsea inspections and data collection, enhancing safety by reducing the need for human intervention in hazardous environments.

Moreover, AI plays a crucial role in environmental monitoring, continuously tracking variables like water quality, air conditions, and seismic activity to minimize environmental risks. As AI technology evolves, it will continue to drive innovations in deep offshore operations, making them safer, more efficient, and environmentally responsible.

Breaking the Myth: Offshore Drilling is Still Fully Manual

Many believe that offshore drilling is a labor-intensive industry requiring heavy manual intervention. However, offshore drilling rigs are becoming more automated thanks to the integration of subsea artificial intelligence and AI-powered systems that optimize efficiency and safety.

The Role of AI in Offshore Operations

AI is redefining offshore oil storage solutions by enabling predictive analytics that monitor oil flow rates, detect pipeline anomalies, and forecast equipment failures. These AI-driven systems significantly reduce downtime and improve production efficiency.

One of the biggest transformations in subsea technology for offshore drilling is using AI in offshore environmental monitoring. Machine learning models analyze oceanic conditions in real time, helping companies adapt their drilling strategies to minimize ecological impact.

AI is also driving automation in offshore gas compression systems, ensuring that gas extraction and storage processes are optimized without human intervention. This shift towards automation is reducing costs, enhancing safety, and making innovations in offshore energy production more viable for the future.

With AI-driven offshore asset integrity management, companies can maintain offshore structures more effectively, preventing unexpected failures. The future of deep offshore technology is not just about depth—it’s about intelligence and sustainability.

The Role of Robotics in Deep Offshore Oil Extraction

Robotics is revolutionizing deep offshore oil extraction by improving safety and efficiency. Remotely operated vehicles (ROVs) and autonomous underwater vehicles (AUVs) perform tasks like subsea inspections and equipment maintenance in hazardous deepwater environments, reducing the need for human intervention. Robotic systems also assist with heavy lifting and automated processes on offshore platforms, streamlining operations. By providing real-time data and enhancing precision, robotics minimizes human error and optimizes oil extraction. As technology advances, robotics will continue to play a key role in making deep offshore oil extraction safer, more efficient, and more sustainable.

Breaking the Myth: Robots Can’t Handle Complex Offshore Tasks

Some believe that robots are not yet capable of handling complex offshore drilling and extraction tasks. However, the latest subsea robotic technology is proving otherwise. Advanced remotely operated vehicles (ROVs) and autonomous underwater robots are now performing delicate tasks with precision, reducing the need for human divers in hazardous conditions.

How Subsea Robotics Improve Safety and Precision in Deep-Sea Oil Extraction

Modern robotic offshore drilling systems are transforming extraction efficiency by automating key tasks, minimizing errors, and improving safety. These robots can conduct underwater welding, inspect pipelines, and even perform maintenance on offshore drilling rigs without human intervention. The use of robotics in deep-sea oil recovery is a game-changer, making extraction more sustainable and cost-effective.

The Evolution of ROV Technology in Offshore Drilling Rigs

Remotely Operated Vehicles (ROVs) have become an integral part of offshore asset integrity management. With advanced cameras, sensors, and robotic arms, ROVs perform subsea well intervention and maintenance tasks that were once deemed impossible. Their ability to function at extreme depths with precision has significantly reduced operational risks and costs.

The Rise of Autonomous Underwater Vehicles (AUVs) in Subsea Well Intervention

AUVs are the next step in offshore automation. Unlike ROVs, which require human control, AUVs operate autonomously using AI-powered navigation and data collection tools. These vehicles are revolutionizing subsea pipeline inspection by enabling continuous monitoring and real-time reporting, ensuring the long-term safety and efficiency of offshore infrastructure.

Innovations in Offshore Renewable Energy Technology

Innovations in offshore renewable energy technology are driving the transition to sustainable energy. Offshore wind farms are advancing with new turbine designs and floating platforms that enable energy generation in deeper waters, where wind conditions are ideal. Tidal and wave energy technologies are also emerging, with new underwater turbines and wave converters capturing ocean currents and waves to produce electricity. Offshore solar panels, designed for marine environments, are adding to the mix, allowing for clean energy generation without using land. These advancements are making renewable energy more efficient, reliable, and scalable, contributing to global sustainability efforts.

Breaking the Myth: Offshore Energy is Only About Oil

The common misconception that offshore energy is solely focused on fossil fuels is rapidly changing. Today, the offshore sector is embracing renewable energy solutions, reducing carbon emissions while meeting global energy demands.

The Growth of Floating Offshore Wind Farms in the Renewable Energy Sector

One of the most significant advancements in offshore power generation is the development of floating offshore wind farms. Unlike traditional offshore wind turbines that require seabed foundations, floating turbines can be deployed in deeper waters, harnessing stronger and more consistent wind patterns. This innovation is driving the expansion of renewable energy in offshore locations that were previously inaccessible.

The Role of Offshore Power Generation in Reducing Carbon Footprints

Offshore wind farms and wave energy converters are revolutionizing offshore renewable energy by offering clean alternatives to fossil fuels. Countries worldwide are investing in offshore energy infrastructure to meet sustainability goals and reduce reliance on non-renewable resources. This shift is crucial for mitigating climate change and ensuring a greener future.

How Offshore Carbon Capture Technology Supports Sustainability in Energy Production

Another key innovation is offshore carbon capture technology, which allows companies to trap CO2 emissions before they reach the atmosphere. These captured emissions are stored beneath the seabed, preventing environmental damage. By integrating carbon capture with renewable energy production, the offshore industry is moving towards a more sustainable and eco-friendly future.

Challenges in Ultra-Deepwater Drilling and Solutions

Ultra-deepwater drilling faces challenges such as extreme depths, high pressure, and environmental risks. Ensuring safety and equipment stability is difficult due to the complex conditions at great depths. Environmental concerns, like potential oil spills, add to the challenge.

Solutions include advanced blowout preventers (BOPs), real-time monitoring systems, and subsea robotics. These technologies help manage risks, ensure better control over drilling, and reduce human exposure to hazardous conditions. Ongoing innovation in materials, AI, and automation continues to improve the safety and efficiency of ultra-deepwater drilling operations.

Overcoming High-Pressure Deep-Sea Drilling Complications

One of the biggest hurdles in ultra-deepwater drilling is handling extreme pressure and temperature conditions. As drilling operations go deeper, the risk of wellbore instability, equipment failure, and uncontrolled blowouts increases. To combat these challenges, companies are investing in high-pressure deep-sea drilling innovations, such as advanced wellbore strengthening techniques, managed pressure drilling (MPD), and real-time AI-driven monitoring systems. These solutions help prevent accidents and improve the efficiency of deep offshore oil exploration.

Advanced Offshore Corrosion Control Techniques

Corrosion is a major issue in deep-sea drilling operations, affecting offshore platforms, pipelines, and drilling rigs. With exposure to seawater, extreme pressure, and fluctuating temperatures, corrosion can weaken structural integrity and lead to expensive repairs or environmental disasters. The industry is adopting cutting-edge offshore corrosion control techniques, such as specialized anti-corrosive coatings, cathodic protection systems, and advanced material selection for pipelines and drilling equipment. These measures ensure long-term durability and reduce maintenance costs.

How Subsea Artificial Intelligence is Minimizing Risks

AI-driven technologies are playing a crucial role in enhancing the safety and efficiency of ultra-deepwater exploration. Subsea artificial intelligence is being used for predictive maintenance, real-time data analysis, and autonomous system monitoring. AI-powered offshore risk assessment tools can identify potential failures in drilling equipment, reducing downtime and preventing catastrophic failures. Additionally, machine learning algorithms help optimize drilling operations by analyzing historical data and making accurate predictions about subsurface conditions.

The Impact of Climate Change on Deep-Sea Exploration

Climate change impacts deep-sea exploration by altering ocean temperatures, currents, and ecosystems, making it harder to predict conditions. Rising temperatures and melting ice affect marine life and can destabilize ocean environments. Additionally, unpredictable weather and harsher conditions may challenge exploration efforts and damage equipment. However, these challenges also push for advancements in exploration technology to better understand and protect deep-sea ecosystems, aiding conservation efforts.

Rising Sea Levels and Their Effects on Offshore Energy Infrastructure

Climate change is causing sea levels to rise, impacting offshore energy infrastructure worldwide. Rising water levels increase the risk of flooding on offshore platforms, corrosion of equipment, and disruptions in subsea oil and gas pipelines. To counter these challenges, companies are investing in climate-resilient offshore infrastructure, including elevated platform designs, reinforced subsea structures, and advanced anchoring systems to withstand extreme weather conditions.

The Need for Marine Oil Spill Prevention in Deep Offshore Operations

As climate change intensifies, extreme weather events pose a greater risk of offshore oil spills. Stronger storms, hurricanes, and unpredictable ocean currents make deep-sea drilling more hazardous. This has led to the development of marine oil spill prevention technologies, such as AI-driven leak detection systems, automatic shut-off valves, and improved blowout preventers. Additionally, companies are deploying eco-friendly oil spill containment methods to minimize environmental impact in case of leaks.

Climate-Adaptive Strategies for Subsea Pipeline Inspection and Maintenance

Subsea pipeline inspection and maintenance are becoming more challenging due to changing oceanic conditions. Rising temperatures and increased ocean acidity can weaken pipeline materials, while shifting seabed conditions may cause pipeline misalignment. To address these issues, companies are employing climate-adaptive offshore maintenance strategies, including AI-powered robotic inspections, self-healing pipeline coatings, and real-time structural health monitoring systems. These innovations help enhance the longevity and reliability of subsea oil and gas infrastructure in a changing climate.

Advanced Safety Systems in Offshore Oil Rigs

Advanced safety systems in offshore oil rigs include real-time monitoring, AI-driven risk assessments, and blowout preventers (BOPs) to prevent accidents and ensure emergency readiness. Robotics and remotely operated vehicles (ROVs) enhance safety by performing inspections and maintenance in hazardous environments. While these systems are costly and require skilled personnel, ongoing innovations in AI and automation continue to improve safety and efficiency, protecting both workers and the environment.

Cutting-edge Subsea Safety Systems

The offshore oil and gas industry increasingly depends on advanced subsea safety systems to ensure operational safety and mitigate risks during critical operations. These systems are designed to react swiftly in emergencies, with many being remotely monitored and controlled from onshore locations. One of the most significant advancements is the implementation of real-time data monitoring systems, which continuously track offshore operations. These systems provide operators with instant alerts when anomalies are detected, enabling them to take proactive action before potential disasters occur. By detecting potential hazards early, these technologies allow operators to respond quickly and effectively.

Role of Offshore Risk Assessment in Preventing Disasters

A robust risk assessment strategy is essential for preventing disasters in offshore operations. With the integration of predictive analytics and sophisticated simulation models, offshore operators can now forecast potential risks and adjust operations accordingly. These risk profiles are built by analyzing a range of factors, such as environmental conditions, historical data, and operational parameters. This level of risk assessment ensures that all possible scenarios are considered, significantly reducing the likelihood of accidents. Furthermore, offshore operators are benefiting from rapid advancements in environmental monitoring technologies. AI-driven systems are now capable of providing real-time updates on subsea conditions, air quality, and other critical factors, helping to maintain safe operations and protect both personnel and the environment.

The Challenges of Advanced Safety Systems

While these systems provide significant improvements in emergency preparedness, they are not without their challenges. One of the primary drawbacks is the high cost associated with their implementation, maintenance, and ongoing training required for personnel. These systems often involve sophisticated hardware and software, which can be expensive to install and operate. Additionally, the complexity of these systems can occasionally result in technical malfunctions, requiring swift intervention. However, as technology continues to evolve, these systems become more reliable, efficient, and capable of handling complex safety situations. The promise of even more advanced safety technologies in the future is strong, further enhancing the safety infrastructure on offshore rigs.

Future of Offshore Safety Systems

The future of offshore safety systems looks highly promising, with continuous advancements in technology. As innovations in AI, machine learning, and real-time monitoring evolve, we can expect even more sophisticated and effective safety solutions to emerge. These systems will further minimize risks, ensure safer operations, and provide more reliable protections for personnel and the environment. As the offshore industry continues to embrace cutting-edge safety systems, the overall safety and efficiency of operations will undoubtedly improve.

How Deep Offshore Technology is Improving Sustainability

Deep offshore technology is improving sustainability by enabling cleaner energy production and reducing environmental impacts. Offshore LNG production provides a cleaner alternative to traditional fossil fuels, emitting fewer pollutants and helping transition to more sustainable energy sources.

Advances in subsea drilling technology have led to the development of eco-friendly drilling fluids, which are less harmful to marine life. Additionally, innovations in deepwater decommissioning processes ensure that rigs are dismantled and sites are cleaned up with minimal environmental disruption.

These technologies are helping the offshore energy industry reduce its carbon footprint and support the global shift toward more sustainable energy practices.

Offshore LNG Production and Clean Energy Initiatives

Deep offshore technology has made considerable progress in improving sustainability, particularly in offshore LNG (Liquefied Natural Gas) production. LNG is a cleaner energy source compared to other fossil fuels, as it produces fewer carbon emissions and pollutants when burned. Offshore LNG production facilities play a key role in the global shift toward cleaner energy sources. These facilities extract natural gas from beneath the seabed and process it offshore, minimizing the environmental impact that would typically arise from land-based operations. Additionally, offshore LNG facilities are increasingly designed with technologies that capture and store carbon emissions, which further supports global sustainability goals.

Sustainable Practices in Subsea Drilling Mud Systems

Sustainable practices in subsea drilling mud systems are also contributing to reducing the environmental impact of offshore operations. Drilling mud plays a crucial role in offshore drilling by maintaining pressure in the wellbore and preventing the release of hazardous substances during drilling operations. Traditional drilling fluids have often posed environmental risks, but innovations have introduced eco-friendly alternatives. These sustainable mud systems are made from biodegradable materials and non-toxic chemicals, making them much less harmful to marine life. By using these environmentally friendly alternatives, offshore companies are significantly reducing their environmental footprint during drilling operations.

The Role of Deepwater Decommissioning in Reducing Environmental Impact

Another critical area in improving sustainability is deepwater decommissioning. As offshore rigs reach the end of their operational life, decommissioning involves the removal of infrastructure, cleaning subsea sites, and repurposing or recycling equipment. This process helps to prevent abandoned rigs from becoming long-term environmental hazards. Decommissioning technologies, such as robotics and automation, have made the process more efficient and safer, enabling companies to dismantle infrastructure without causing significant disruption to marine ecosystems. Additionally, there is growing interest in repurposing old rigs as artificial reefs, which can foster marine biodiversity and contribute positively to the surrounding ecosystem.

Challenges in Implementing Sustainable Offshore Technologies

Although these sustainable technologies show great promise, they come with challenges. One of the biggest hurdles is the high cost associated with implementing these advanced systems, particularly for smaller operators. The development and installation of eco-friendly technologies can be expensive, and for companies operating on thin margins, this may not always be feasible. Moreover, some of these technologies are still in the development phase and may require further research to ensure their effectiveness. Despite these challenges, the offshore energy sector’s continued focus on sustainability will likely lead to more affordable and effective solutions in the future.

The Promise of a More Sustainable Offshore Industry

In conclusion, deep offshore technology has made significant strides toward improving sustainability. From cleaner offshore LNG production to eco-friendly subsea drilling practices and responsible decommissioning methods, these innovations are making a real difference in reducing the environmental impact of offshore operations. While challenges remain, such as high costs and the need for further technological advancements, the future of the offshore energy industry looks greener. As technology continues to evolve, these sustainable practices will likely become the norm, ensuring a cleaner and more environmentally friendly offshore energy industry for generations to come.